-40%

DCC Concepts DCS-S100 Low Melt 100 Deg. low Temp Solder for White Metal Etc 1st

$ 9.11

- Description

- Size Guide

Description

MenuHome

About Us

Returns

Contact Us

View Feedback

Add to Favourites

DCC Concepts DCS-S100 Low Melt 100 Deg. Low Temp Solder for White Metal Etc

Main Description

DCC Concepts DCS-S100 Low Melt 100 Deg. Low Temp Solder for White Metal Etc

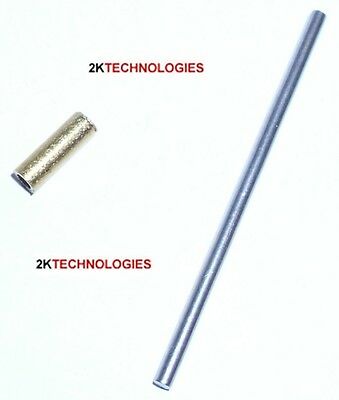

Sapphire 100 (Low Temp Solder)

Sapphire 100 is an exciting solder which is designed for use on white-metal and similar alloys. We worked hard to make sure that its composition coexists better with brass than conventional 70 degree low melt solders, so while tinning is still recommended for larger joints this solder will work without pre-tinning so it is not always essential for smaller parts.

Its low temperature gives the ability to solder quickly and well without heating up the white-metal too much. It reacts differently and it can be re-worked… Because unlike 70 degree solder it will not combine with the white-metal and produce a weak ‘sludge’, so joints end up stronger.

Clean the white metal properly and use a good flux and you will also find it has much better flow and needs less per joint than conventional WM solder! We hope you like the way we present it – we often find that with bar solders even we cannot tell which one is which, so we cast it into a shape that makes it impossible to forget.

Use DCCconcepts Sapphire flux with this solder for excellent results!

made with love by

jarilo

design

jarilo

design

DCC Concepts DCS-S100 Low Melt 100 Deg. Low Temp Solder for White Metal Etc Sapphire 100 (Low Temp Solder)Sapphire 100 is an exciting solder which is designed for use on white-metal and similar alloys. We worked hard to make sure that its composition coexists better with brass than conventional 70 degree low melt solders, so while tinning is still recommended for larger joints this solder will work without pre-tinning so it is not always essential for smaller parts.Its low temperature gives the ability to solder quickly and well without heating up the white-metal too much. It reacts differently and it can be re-worked… Because unlike 70 degree solder it will not combine with the white-metal and produce a weak ‘sludge’, so joints end up stronger.Clean the white metal properly and use a good